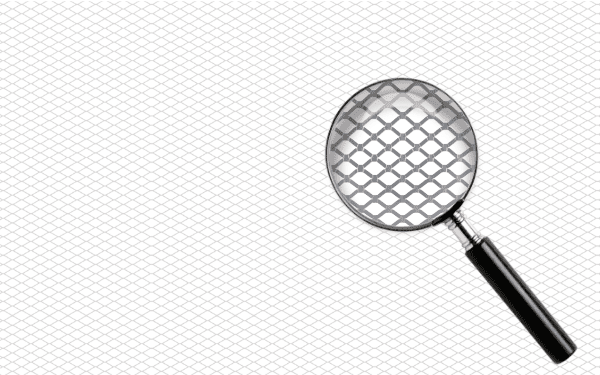

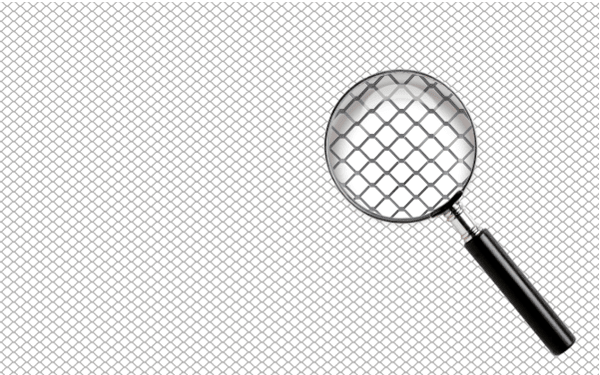

Classical and the most popular micro expanded metal mesh openings.

At Yilida, we currently have 34,000 square meters of manufacturing, innovating and office area under construction. To serve our customers better, we have 25 production lines and 50 units of equipment to supply 5,000,000 square meters annual output and 13 R&D staff for product innovation and developing. Learn Yilida capacity and match with your requirements. If you can't find your satisfied information, just contact us for customized service. We are willing to develop products together with you.

Copper

Brass

Silver

Aluminum

Galvanized

Nickel

Stainless Steel

Titanium

Other Alloy

Other Alloy

Classical and the most popular micro expanded metal mesh openings.

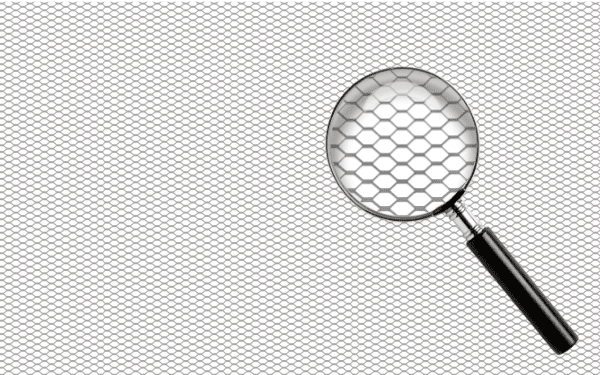

Specially design for applications that need a large free cross-section.

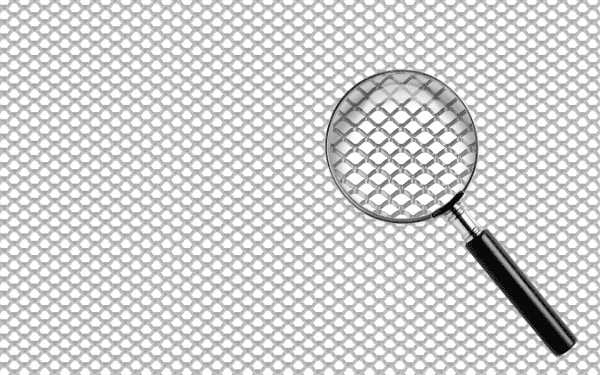

Supplies perfect balance between material and carrying capacity.

It can perfectly replace the perforated metal sheets.

Material: Copper, Aluminium, Nickel, Titanium, Silver, Stainless Steel

(thinnest 0.35 mm on Low Carbon Steel)

Ultra-Thin Series: Copper, Aluminum and Other Foils

Cut raw material coils into sheets/plates and custom length for the next process of micro expanded metal.

Standard and independently improved machines satisfy different thicknesses, opening sizes, width and length.

Leveling machine can make the micro expanded metal into a flat sheet with minimal wave and buckle.

Flatten 3D micro expanded metal into flattened products for reducing overall thickness and specific applications.

Wrap the micro expanded metal roll into tightened rolls and prepare for the following package progress.

Slit the micro expanded metal into stripes for specific applications. The maximum slit width is 1300 mm.

Cutting sheet or rolls of micro expanded metal into pieces as request. Max. Diameter of piece is 1300 mm.

Bending the sheets into specific shapes. The maximum width of micro expanded metal to bending is 3200 mm.