Yilida Metal Wire Mesh Co., Ltd. was established in 1984, committed to micro expanded metal production. Strict Quality Control and process improvement, and has accumulated rich experience in the industry make our products with accurate size, small tolerance, advanced technology and other advantages.

The company Yillida has advanced and stable high-speed punching equipment and has a series of independently improved equipment to meet the different needs of customers. Usually, our production is going on 24 hours (25 production lines working alternation and workers work round the clock in three shifts), which can deliver large quantities of products in a short time.

Yilida has a R&D team of 13 people, whose members are involved in mechanical manufacturing, electrical engineering, non-standard automation and other fields. Our R&D team is committed to providing customers with better technology and lower cost solutions.

We are committed to providing our customers with better micro expanded metal solutions to increase their profitability and enable them to gain a competitive advantage in their respective industries. Our micro expanded metal solutions are widely used in aerospace, wind energy, electromagnetic shielding, automotive, filtration, acoustics and other fields.

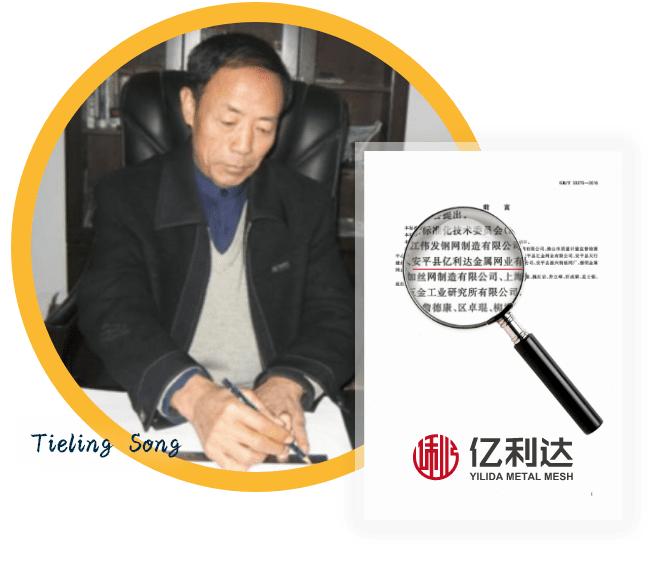

To assist the development of the industry, and s, Mr. Song Tieling, chairman of Yilida, and his team actively offered suggestions and suggestion and became one of the important drafting enterprise in the new national standard (GB/T 33275-2016) by summarizing the experience and data accumulated in the past, making a contribution to promote the standardized production of the industry.

Yilida has a complete line of precision micro expanded metal, which can produce products of different sizes and thicknesses, with an annual output of 5 million square meters.

We can provide stainless steel, titanium, nickel, zirconium, aluminum, copper, carbon steel and other materials of precise expanded metal, and provide chrome plating, platinum plating, titanium plating, electrostatic spraying and other surface treatment process to meet the various needs of customers.

Focus on micro expanded metal, expanded metal & perforated metal production.

Committed in developing and innovating more products and applications for customers.

Imported and independent improved equipment guarantee the stable supply and accurate quality.

Help to reduce production loss, improve production efficiency and decrease products tolerance.

Satisfy continuously increasing orders, production needs and innovating input.

Satisfy large and urgent orders and serve better for our customers all over the world.

Professional, focus and enthusiastic bring us continuous improvement and development. Every progress has been recorded by our customers' satisfaction and long-term cooperation.

We insist on consistent improvement to make perfection more perfect

All materials are purchased from large steel factory to guarantee the good chemical and physical properties.

The mould is made from imported moulding steel and EDM technology, Every mould will be checked before producing and guarantee the accurate punching result and smallest tolerance.

After treated with sophisticated flatten machine, the mesh surface will be flattened and no any burrs.

Sophisticated hydraulic cutting machine can cut accurate sizes according to customers' request strictly.

All products will be packed well including waterproof package, shake proof, impact resistance package and other package measure to guarantee the best performance of micro expanded metal.

Our professional quality control staff will 100% inspect products according to enterprise standard which is far higher than industrial and international standard and process.

Materials of every order will be recorded along with the mill certification and test report to guarantee each batch goods have same quality.

During the production process, the mould is easy abrasion and broken. We will regular replace the moulds to avoid deformation, nicks and burrs.

We have the biggest width (4000 mm) flatten machine to meet the leveling demand of large width meshes.

Independent improved cutting machine and 500+ production moulds can minimize the tolerance during production and cutting.

Each order we will customize the package according to the product material, chemical and physical property, transport distance and method as well as customers' specific requirements.

All inspection results will be recorded and stored for the next preventive measures and traceability.