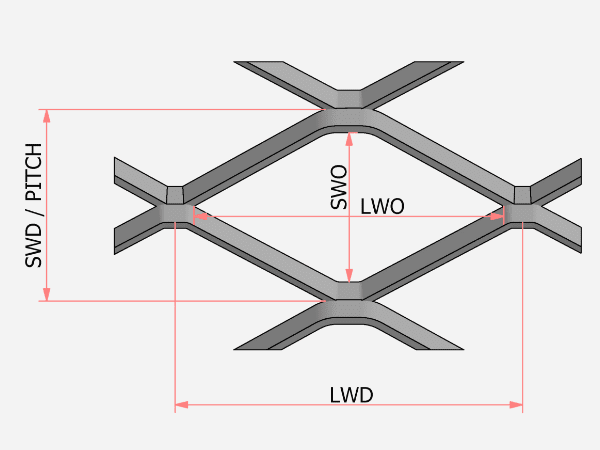

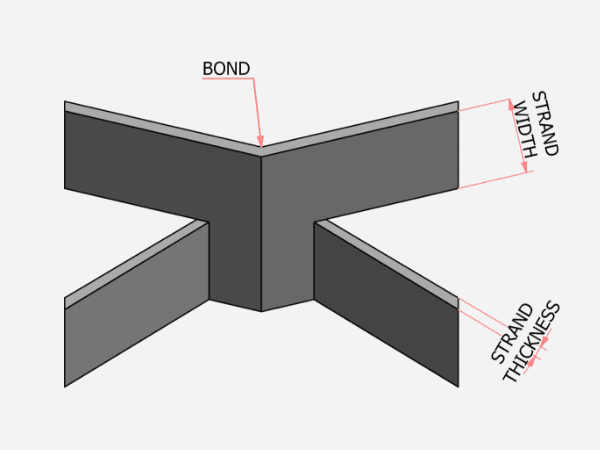

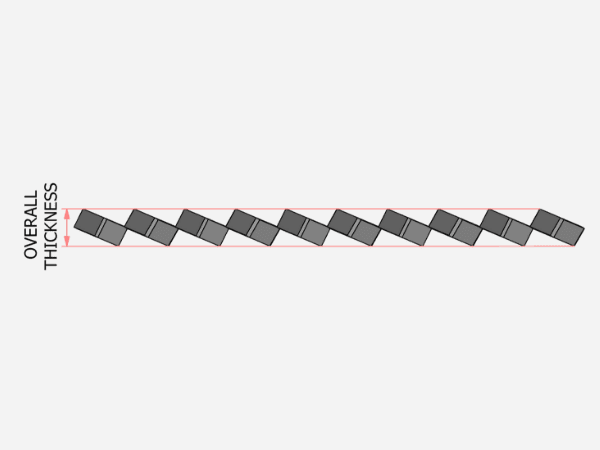

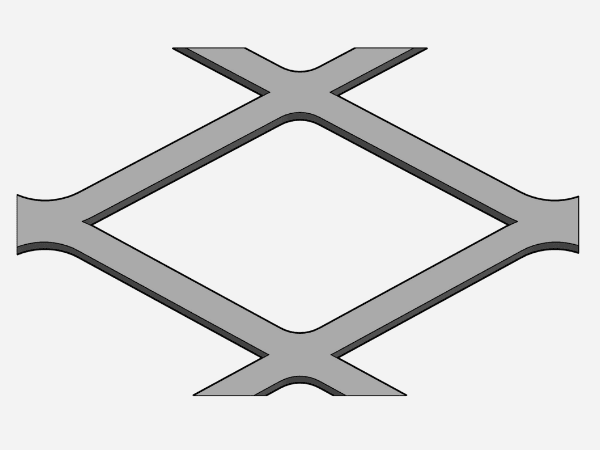

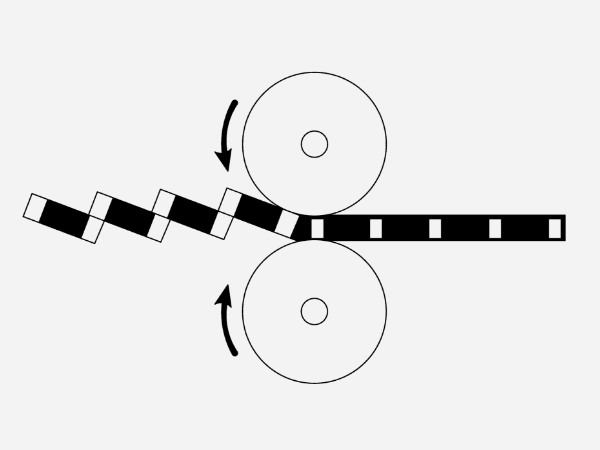

Amount and dimensional (US/Metric) length fed between the upper and lower tooling to produce the mesh. The strand width is the amount of metal slit from the parent metal in forming the mesh. This is closely controlled and is directly related to the weight, overall thickness and open area as shown in the above illustration.