Carbon fiber composite material has become the main material of aircraft. But the composite material is a poor conductor of the current and easy to be damaged in the lightning strikes. Micro expanded metal covers on the surface of composite material to dissipates the lightning strikes, prevent lightning striking damage, supply protection to composite material, and extend aircraft critical components' safe.

It is widely used in the aerospace for aircraft manufacturing at fuselage, wing, engine compartment, flaps, wing tip, even the rotating blades and body parts of the helicopter.

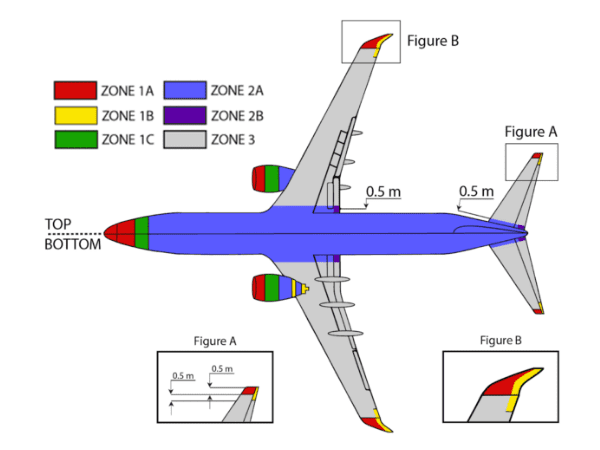

According to the SAE ARP 5414 standard, the aircraft surface is divided into three zones: zone 1A, Zone 1B-1C-2A-2B and zone 3. and we will recommend the different types of micro expanded metal mesh for different zones for the best performance.

Apart from the above specifications, we will manufacture and custom the micro expanded metal in aluminum or copper material for your specific requirements and model.

| Product Code | Weight (g/m2) | Material | LWD (mm) | Overall Thickness (mm) | Open Area | Length (m) |

|---|---|---|---|---|---|---|

| YASAL-49 | 49 | Aluminum 1060 | 2.0 | 0.10 | 64% | 80–300 |

| YASAL-78 | 78 | Aluminum 1060 | 2.0 | 0.15 | 68% | 80–300 |

| YASAL-136 | 136 | Aluminum 1060 | 2.0 | 0.15 | 63% | 80–300 |

| YASAL-36 | 36 | Aluminum 1060 | 2.0 | 0.04 | 64% | 80–300 |

| YASCU-78 | 78 | Pure Copper | 2.5 | 0.10 | 85% | 80–300 |

| YASCU-107 | 107 | Pure Copper | 2.5 | 0.13 | 78% | 80–300 |

| YASCU-140 | 140 | Pure Copper | 3.2 | 0.13 | 77% | 80–300 |

| YASCU-195 | 195 | Pure Copper | 2.5 | 0.13 | 70% | 80–300 |

| YASCU-390 | 390 | Pure Copper | 3.2 | 0.33 | 55% | 80–300 |

| YASCU-420 | 420 | Pure Copper | 3.2 | 0.33 | 53% | 80–300 |

| YASCU-815 | 815 | Pure Copper | 3.2 | 0.25 | 64% | 80–300 |

| YASCU-78F | 78 | Pure Copper | 2.5 | 0.05 | 85% | 80–300 |

| YASCU-107F | 107 | Pure Copper | 2.5 | 0.05 | 78% | 80–300 |

| YASCU-140F | 140 | Pure Copper | 3.2 | 0.08 | 77% | 80–300 |

| YASCU-195F | 195 | Pure Copper | 2.5 | 0.08 | 70% | 80–300 |